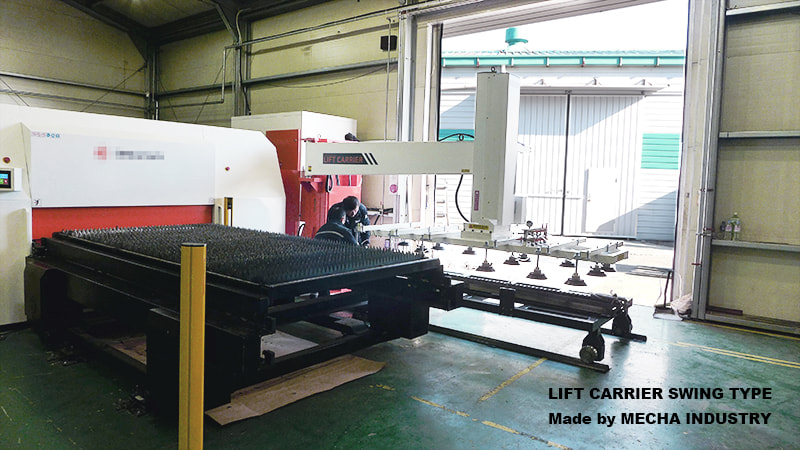

LIFT CARRIER ; SWING TYPE

It consists of a lift carrier body and a loading platform (rail + truck).

The loading table can conveniently move the plate to an appropriate location manually / automatically (optional).

Improve the accuracy of the loading position, reduce labor costs, reduce cost, and improve productivity by automating plate loading!

The loading table can conveniently move the plate to an appropriate location manually / automatically (optional).

Improve the accuracy of the loading position, reduce labor costs, reduce cost, and improve productivity by automating plate loading!

WHY?

FOR BETTER CONTROL OF METAL SHEET!

1. TOUCH PANEL OPERATION

With touch screen panel, it performs quantity take-off tasks (loaded sheet counting), working status check,

auto/manual operation.

2. INTERWORK FEATURE

It adopts interwork feature with cutting, NCT turret punching machines.

3. EXACT AND FLEXIBLE MOVEMENT

Sheet separator equipped on Lift Carrier makes easy to do a sheet transfer.

4. IMPROVEMENT OF WOKING ENVIRONMENT

Our solution, Lift Carrier, optimize your productivity to reduce the time of loading materials, the cost of labor,

the space of crane/forklift etc.

5. EASY LOADING OF METAL SHEET

Automatic / manual loading for supplying metal sheet to cutting machines can be easily operated with control

stand.

With touch screen panel, it performs quantity take-off tasks (loaded sheet counting), working status check,

auto/manual operation.

2. INTERWORK FEATURE

It adopts interwork feature with cutting, NCT turret punching machines.

3. EXACT AND FLEXIBLE MOVEMENT

Sheet separator equipped on Lift Carrier makes easy to do a sheet transfer.

4. IMPROVEMENT OF WOKING ENVIRONMENT

Our solution, Lift Carrier, optimize your productivity to reduce the time of loading materials, the cost of labor,

the space of crane/forklift etc.

5. EASY LOADING OF METAL SHEET

Automatic / manual loading for supplying metal sheet to cutting machines can be easily operated with control

stand.