What is Welding Carrier?

When we need this equipment?

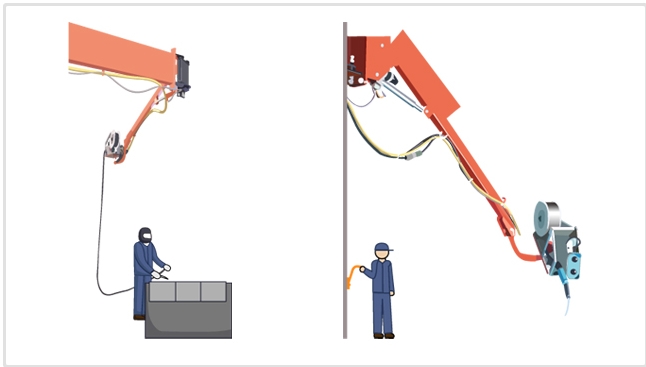

The Welding Carrier is a welding auxiliary handling equipment, helping welders to carry the heavy feeder, gas hoses, and cables with less force.

USERS of WELDING CARRIER

- Sheet Metal Companies with small workplace

- Companies with a wide operating radius

For example, some factories in the field of manufacturing 'car lifting/parking system' have difficulty of carrying welding feeder, cables, and gas hoses to the weldment at higher place.

However, if you use Welding Carrier, you can just move around with a welding torch by keeping this convenient equipment

high up.

However, if you use Welding Carrier, you can just move around with a welding torch by keeping this convenient equipment

high up.

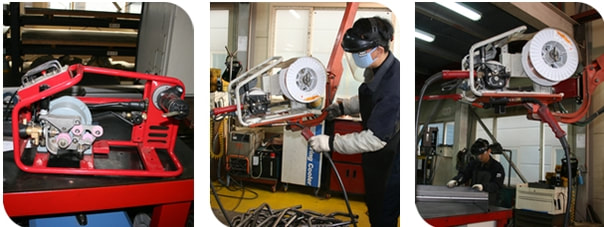

Putting the wire feeder of welding m/c and suspending gas hoses and cables on Welding Carrier

The workers move and carry the wire feeder of welding machine, cables and gas hoses frequently at welding workshop, which require time and labor as well as the risks occurring in moving the welding machine up to elevated work platforms. Welding Carrier has eliminated all these problems with its unlimited movement – up/down, right/left, front/back.

The workshop will become cleaner and tidier with well-arranged cables and hoses on Welding Carrier, and much safer from electrical accident.

The workshop will become cleaner and tidier with well-arranged cables and hoses on Welding Carrier, and much safer from electrical accident.

- Welders inefficiently move cables, gas hoses, welding feeder a lot

- Companies consider 'safe and clean workplace' as their first priority

- Educational institutions of welding which want safe educational place

- Shipbuilding companies and heavy industrial companies dealing with large weldment